Past Projects

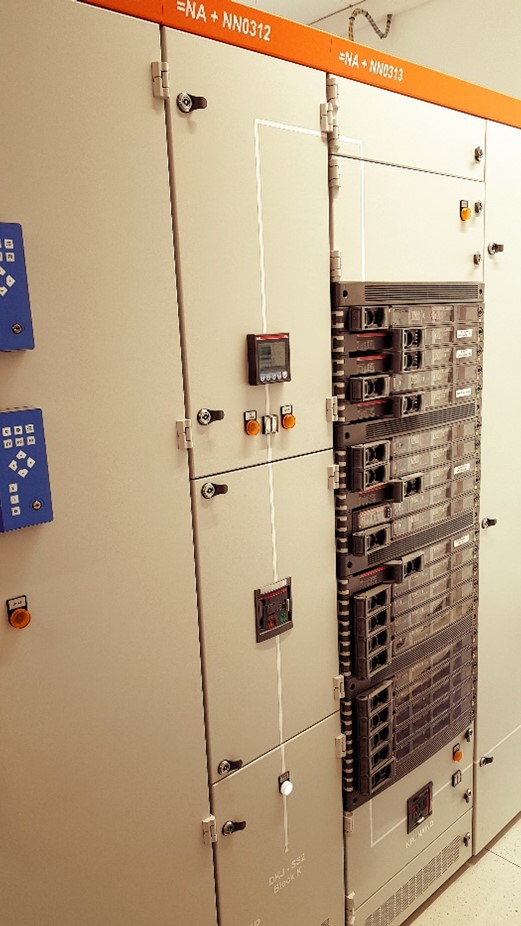

Supply of a 400V AC NSHV in MCC technology

- Consumer outlets in MCC technology

- design verification according to IEC 61439-1/2

- integrated automatic changeover

- integration into the control system

- installation incl. cable laying and connection work

- engineering, documentation and project management

Integration of a 220V DC NSHV system

- Consumer outlets in MCC technology

- design verification according to IEC 61439-1/2

- Diode coupling

- Integration into the control system

- Installation incl. cable laying and connection work

- Tying out and dismantling of the old system incl. temporary solution

- engineering, documentation and project management

Setting up a 220V DC battery system

- closed lead acid batteries with 800Ah

- ceramic funnel plug

- earthquake proof frame

- conductive battery bottom incl. measurement

- VEXAT document preparation

- project management, assembly and documentation

Construction of a stationary emergency power system

- 600kVA genset power

- Separation of tank room from genset room in F90 design

- Design according to Stage 3A emissions

- Sound insulation 75dB in 10m distance

- Control cabinet design according to machine guidelines

- Planning, delivery and assembly

Supply of a mobile backup power supply system

- design and delivery of 4 pcs. 60kVA units

- max. permissible trailer load: 2.000kg

- max. tank volume 200l

- designed for mains parallel operation

- powerlock plug niche

- engineering, delivery, registration and training

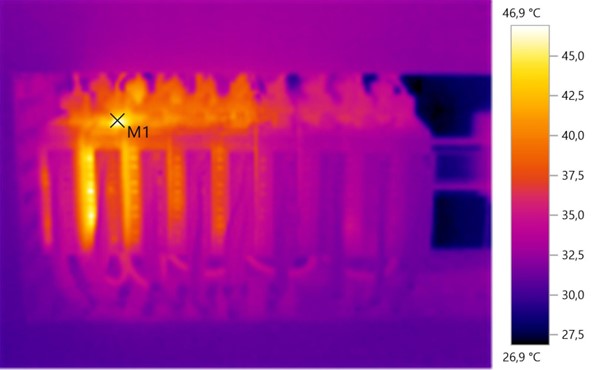

Maintenance of a standby power supply system

- Control cabinet checked with thermal imaging camera

- Messages checked

- Error memory read out

- mech. components serviced

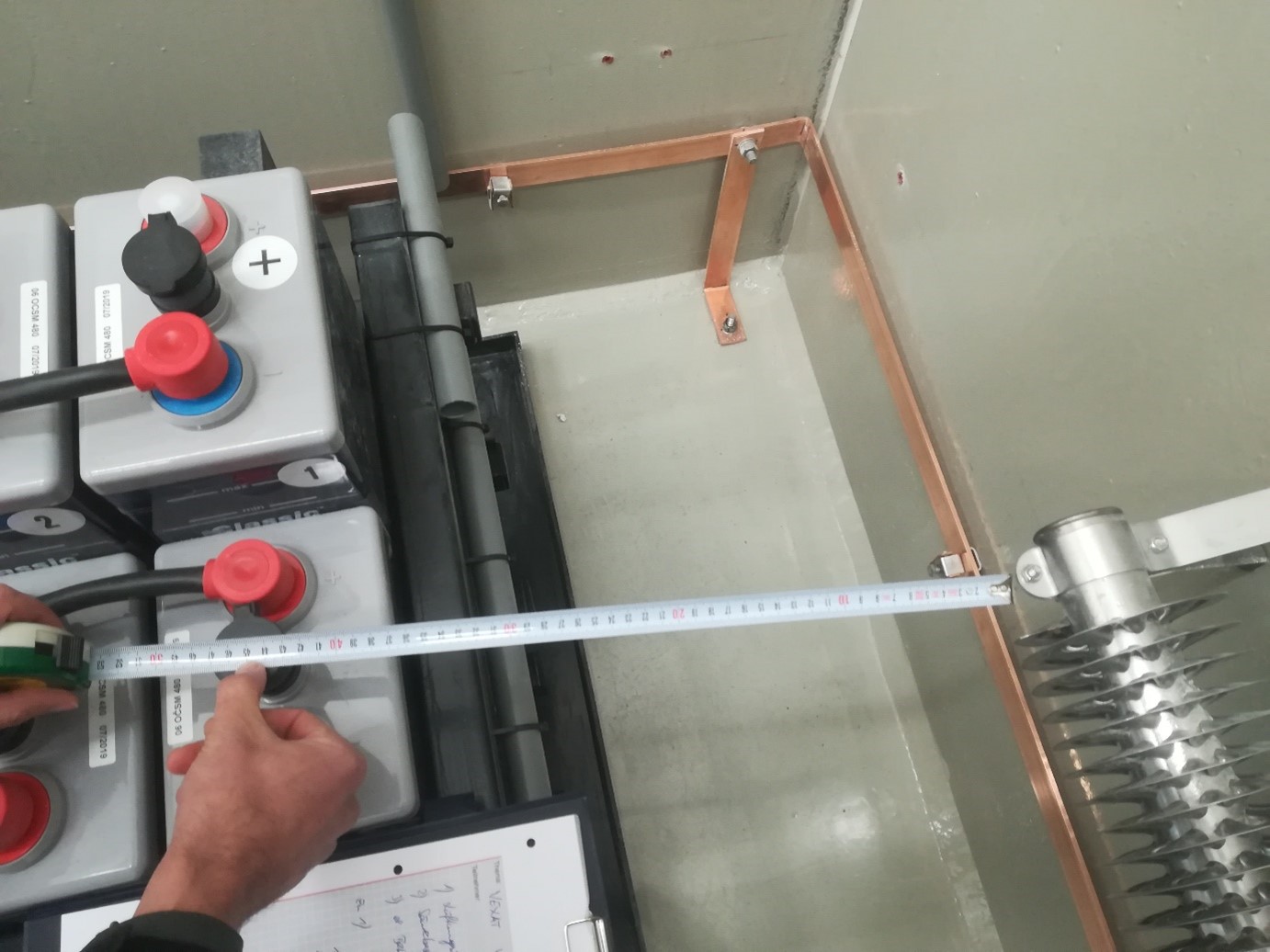

Checking the batteries

- Maintenance according to manufacturer’s instructions

- Electrolyte density, nominal voltage, temperature

- capacity test by means of Torkel meter

- measurement of battery bottom leakage resistance

- report generation

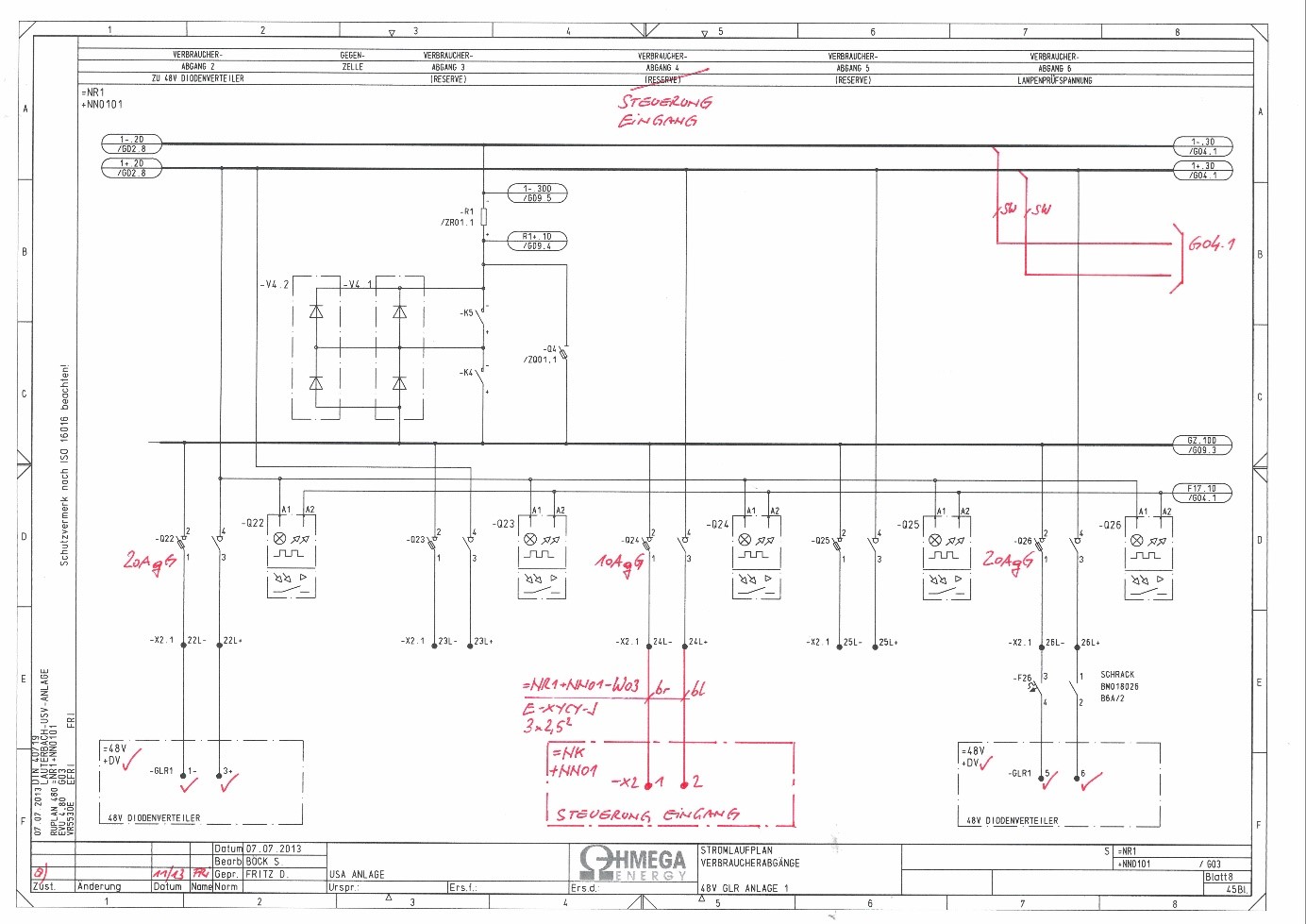

Documentation tracking

- Circuit diagram creation on RUPLAN EVU module

- Front views on ACAD

- Cross-connection diagrams

- Customer-specific document structure

Testing of the electrotechnical system

- thermographic examination for contact resistances

- functional check of switchings and signaling system

- terminal check

- test report according to electrical protection ordinance

Engineering, assembly and IBN of an MSPG plant

- Medium voltage switchgear according to ÖVE/ÖNORM E8383

- Operating voltage: 20kV

- Ur = 24kV

- Ir = 1250A

- Production plans created on RUPLAN EVU module

- Incl. cable laying and connection work

- Integration into the control system

VEXAT document creation

- Zone definition

- primary explosion protection

- secondary explosion protection – avoidance of ignition sources

- Checking the structural design

- Implementation of organizational measures

- Preparation of protocols

Circuit breaker - Maintenance

- Checking the mechanical components

- Contact wear check

- Interlocking

- Trigger test with primary test system

- Preparation of protocols

Construction of a prototype - SF6 power supply monitoring

- Methanol fuel cell generator

- Nominal voltage 12/24 VDC

- Rated charging power 110W

- Solar panel 310Wp

- incl. remote modem antenna

- concept development

- Test runs and modernization

- Installation, commissioning and training

Structured cabling - data center

- IT- Fiber optic cable

- IT- patch panel 19″

- splicing work

- Measurement LWL OTDR MM

- Cabling and measurement

Construction of a 230V inverter distribution system

- Setup with IT network form

- ISO fault monitoring and location

- Number of consumer outlets 48

- Parameterization and integration into the control system

- Engineering, installation, cabling and documentation

Embedding a data collector cabinet

- Specification creation

- FAT factory acceptance

- check messages

- Installation incl. cable laying and connection work

- Engineering, documentation and project management

Supply of a 220V DC rectifier system

- in modular technology

- counter cell control

- customized system design

- integrated consumer outlet field

- integration into the control system

- installation incl. cable laying and connection work

- Dismantling and dismantling of the old system incl. provisional solution

- Engineering, documentation and project management

Planning of a transfer cabinet

- Outdoor cabinet

- Switching between mobile and stationary emergency diesels

- Powerlock plug niche

- Integration into the control system

- Delivery, installation and commissioning

Renewal of the automatic changeover

- 400V automatic transfer switch incl. control system connection

- Field control unit SICAM

- Integration into the control system

- Engineering, supply, installation and IBN

Renew 48V rectifier system

- Helicopter transport to the radio station

- 2 rectifiers and 2 stationary battery systems

- Check low voltage distribution

- Engineering, supply, installation and IBN

400V AC auxiliary power supply

- Consumer outlets in insert technology

- Design verification according to IEC 61439-1/2

- Integration into the control system

- Installation incl. cable laying and connection work

- Engineering, documentation and project management

Supply of a UPS system

- consisting of an IGBT rectifier and inverter

- rated voltage 400V

- Rated power 132kW

- battery circuit 630A

- consumer circuit 500A

- I&C integration IEC -60870-5-101 balanced

- Project management and documentation