Past Projects

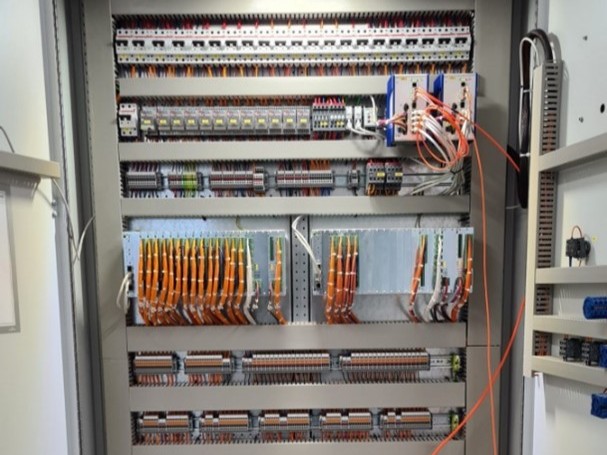

Delivery of a 400V AC LV Switchgear in MCC Technology

- Outgoing feeders in MCC design

- Type testing according to IEC 61439‑1/2

- Integrated automatic transfer system

- Integration into the control system

- Installation including cable laying and connection work

- Engineering, documentation and project management

Integration of a 220V DC LV Switchgear System

- Outgoing feeders in MCC design

- Type testing according to IEC 61439‑1/2

- Diode coupling

- Integration into the control system

- Installation including cable laying and connection work

- Decommissioning and dismantling of the old system including temporary solution

- Engineering, documentation and project management

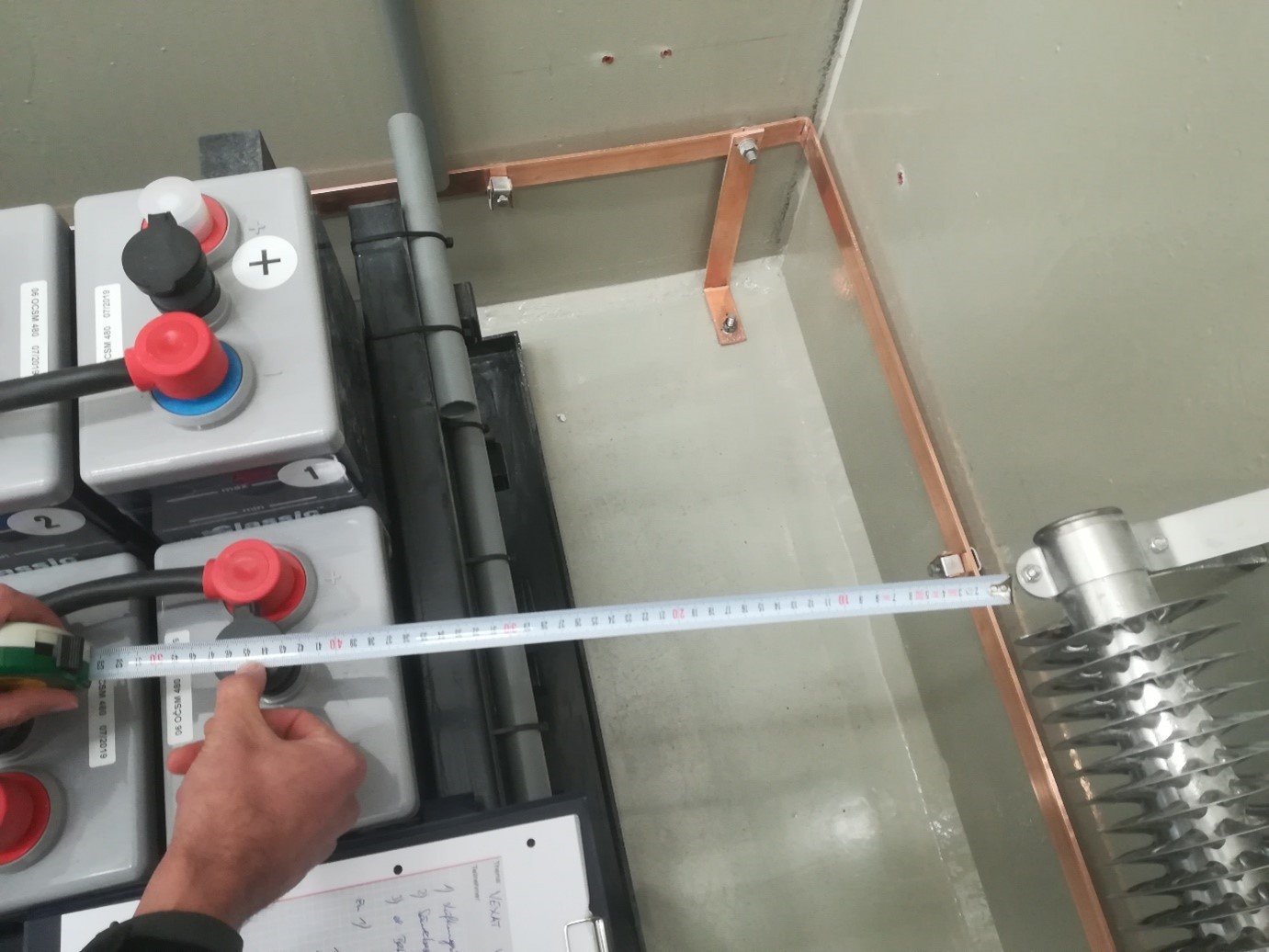

Installation of a 220V DC Battery System

- Sealed lead‑acid batteries, 800 Ah

- Ceramic vent plugs

- Earthquake‑resistant rack

- Conductive battery room flooring incl. measurement

- VEXAT documentation

- Project management, installation and documentation

Construction of a Stationary Backup Power System

- 600 kVA generator output

- Fire‑rated separation between tank room and generator room (F90)

- Execution according to Stage 3A emission standards

- Sound level: 75 dB at 10 m distance

- Control cabinet built according to machinery directives

- Planning, delivery and installation

Delivery of a Mobile Backup Power System

- Planning and delivery of 4 units, each 60 kVA

- Maximum permissible trailer load: 2,000 kg

- Maximum tank volume: 200 L

- Designed for grid‑parallel operation

- Powerlock connection panel

- Engineering, delivery, registration and training

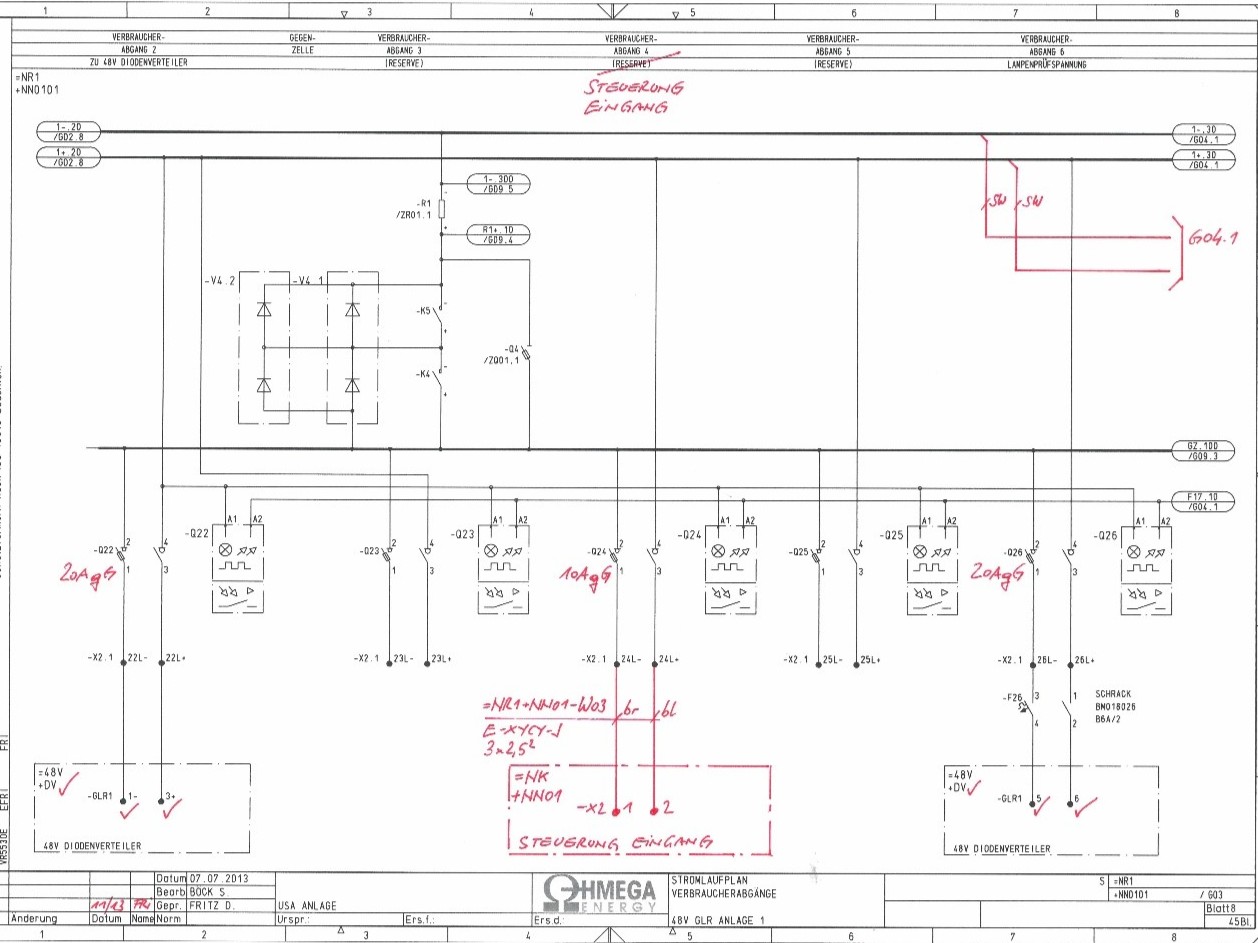

Maintenance of a Backup Power System

- Inspection of the control cabinet using a thermal imaging camera

- Monitoring of system messages

- Reading of error memory

- Maintenance of mechanical components

Battery Inspection

- Maintenance according to manufacturer specifications

- Electrolyte density, nominal voltage, temperature

- Capacity test using Torkel test device

- Measurement of battery floor insulation resistance

- Test report creation

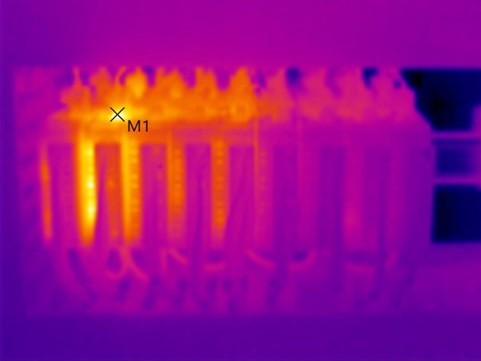

Documentation Update

- Creation of wiring diagrams using RUPLAN EVU module

- Front views in ACAD

- Cross‑connection diagrams

- Customer‑specific documentation structure

Testing of the Electrical Installation

- Thermographic inspection for transition resistances

- Functional testing of switching and alarm systems

- Terminal inspection

- Test report according to electrical safety regulations

Engineering, Installation and Commissioning of an MV Switchgear System

- Medium-voltage switchgear according to ÖVE/ÖNORM E8383

- Operating voltage: 20 kV

- Ur: 24 kV

- Ir: 1250 A

- Creation of manufacturing plans using RUPLAN EVU module

- Including cable laying and connection work

- Integration into the control system

VEXAT Documentation Preparation

- Zoning determination

- Primary explosion protection

- Secondary explosion protection – avoidance of ignition sources

- Inspection of structural implementation

- Implementation of organizational measures

- Documentation and report creation

Circuit Breaker – Maintenance

- Inspection of mechanical components

- Contact wear inspection

- Interlocking

- Trip testing with primary test system

- Report creation

Construction of a Prototype: SF6 Power Supply Monitoring

- Methanol fuel cell generator

- Nominal voltage: 12/24 V DC

- Nominal charging power: 110 W

- Solar module: 310 Wp

- Including remote modem antenna

- Concept development

- Test runs and modernizations

- Installation, commissioning and training

Structured Cabling – Fiber Optics for Data Center

- IT fiber optic cabling

- IT patch panel 19″

- Splicing work

- Fiber measurement LWL OTDR MM

- Cabling and measurement

Construction of a 230V Inverter Distribution System

- Built with IT earthing system

- Insulation fault monitoring and location

- Number of outgoing feeders: 48

- Parameterization and integration into the control system

- Engineering, installation, cabling and documentation

Integration of a Data Collector Cabinet

- Creation of requirements specification

- FAT (Factory Acceptance Test)

- Verification of system messages

- Installation including cable laying and connection work

- Engineering, documentation and project execution

Delivery of a 220V DC Rectifier System

- Modular design

- Counter‑cell control

- Customized system configuration

- Integrated outgoing feeder panel

- Integration into the control system

- Installation including cable laying and connection work

- Decommissioning and dismantling of the old system including temporary setup

- Engineering, documentation and project execution

Design of a Transfer Cabinet

- Outdoor cabinet

- Transfer switching between mobile and stationary emergency diesel systems

- Powerlock connection interface

- Integration into the control system

- Delivery, installation and commissioning

Renewal of the Automatic Transfer System

- 400V automatic transfer system incl. control system integration

- Field control device: SPRECON‑E‑C

- Engineering, delivery, installation and commissioning

Renewal of a 48V Rectifier System

- Transport to the radio station by helicopter

- 2 rectifiers and 2 stationary battery systems

- Inspection of the LV distribution

- Engineering, delivery, installation and commissioning

400V AC Auxiliary Power System

- Outgoing feeders in withdrawable (plugin) technology

- Type testing according to IEC 61439‑1/2

- Integration into the control system

- Installation including cable laying and connection work

- Engineering, documentation and project execution

Delivery of a UPS System

- Consisting of an IGBT rectifier and inverter

- Nominal voltage: 400 V

- Nominal power: 132 kW

- Battery circuit: 630 A

- Load circuit: 500 A

- Control system integration via IEC 60870‑5‑101 balanced

- Project execution and documentation

Photovoltaic System – Substation Weibern

- Output: 162 kWp

- 360 modules at 450 Wp each

- AC distribution cabinet

- Integration via power plant controller into the NetzOÖ grid

- Integration into the customer’s control system

Photovoltaic System – Substation Pongau

- Output: 70.98 kWp

- 156 modules at 455 Wp

- Installed on sliding bracket roof

- Integration into the customer’s control system

Photovoltaic System – Substation Wagenham

- Output: 63.7 kWp

- 140 modules at 455 Wp

- Installed on sliding bracket roof

- Integration into the customer’s control system